Main page content

Entity view (Content)

Timber Construction

Entity view (Content)

Mass timber construction is becoming an increasingly popular construction method because of the multiple advantages it can bring. Mass Timber is sustainable and reduces the carbon dioxide emissions in the building sector, cuts the waste and pollution during construction. As mass timber elements are lightweight and prefabricated, much shorter project timelines and safer construction sites are possible, making it a very cost-effective construction method.

However, historically, wooden constructions have offered poor acoustic isolation levels; particularly at lower frequencies where the lightweight wall and floor panels transmit low frequency noise very efficiently and make it challenging to comply with local building regulations.

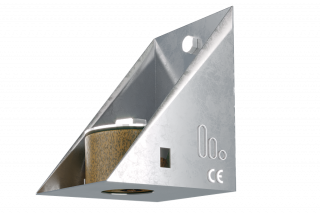

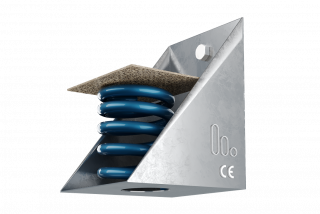

CDM Stravitec offers several solutions to acoustically isolate timber construction, ranging from resilient ceiling hangers, wall strips, floating floor systems and brackets to connect walls, floors or different CLT modules.

As part of our commitment to make your world a quieter place, we continue to invest in several R&D projects to develop sustainable, cost-effective and environmentally responsible isolation solutions for wooden framed and cross-laminated timber structures.

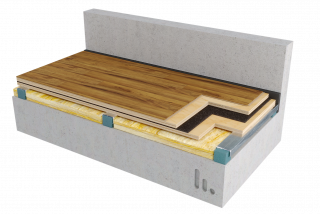

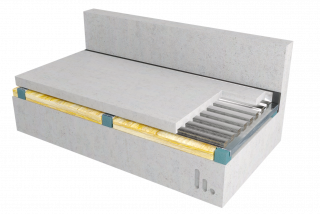

Acoustic floating floors are often used in cross-laminated timber (CLT) construction to provide sound insulation and reduce noise transmission between floors.

The use of an acoustic floating floor system can provide a number of benefits in CLT construction. For example, it can help to reduce the transmission of impact sound between floors, which can be particularly important in multi-story buildings. It can also help to reduce airborne sound transmission, such as voices and music, which can improve the overall acoustic comfort of the building.

The demand for sustainable building materials in the construction industry is growing each year. The popularity of CLT can be partially explained by this growing trend. However, mass timber poses some rather unique challenges in terms of acoustics. Compared to more traditional building materials such as steel and concrete, it is lightweight and a relatively stiff material, which in terms of acoustics is a disadvantage as it allows for easy transmission of vibrations and noise. The use of a concrete floating slab on top of a CLT structure is an easy way to add mass to the overall construction and increase its stiffness. The extra mass does indeed help to improve the overall sound level, but it is far from the fastest and most sustainable option.

Visit Stravi-dB for more information on CLT-assemblies in combination with lightweight floating floors and learn how these are a worthy alternative to concrete to achieve satisfactory sound insulation. Various setups using mainly dry screeds, as these are a more sustainable solution, easier and quicker to install, and less dense than concrete screeds were tested.

-

Information Available to Download

Case Studies

Related Solutions

Request our Technical Bulletin now!

This bulletin, which summarizes the key-findings of an extensive test campaign studying the acoustical performance (airborne sound reduction and impact noise isolation) of lightweight Stravifloor systems in combination with cross-laminated timber slabs serves as a guide to those looking to acoustically improve wooden constructions.