Main page content

Entity view (Content)

Mechanical Equipment

Entity view (Content)

Modern buildings cannot function effectively without essential building services equipment - all of which produce noise and vibrations and, in many instances, are in close proximity to noise sensitive spaces.

The high isolation standards for building components means the existing background noise level inside apartments is becoming lower and consequently even the smallest building service equipment can generate annoyance.

Noise isolation measures are generally implemented for the health and wellbeing of the building’s occupants; however vibration isolation is usually a mandatory requirement for structural integrity/stability and the protection of sensitive equipment.

The dynamic parts of mechanical equipment will inevitably generate noise and vibration and, as they are usually mechanically secured to the supporting structure, high levels of structure-borne noise and vibration are likely. In order to mitigate this potential noise nuisance these machines, and their associated connections, must be decoupled from the supporting structure.

Examples of building services and mechanical equipment are: electrical transformers, generators, heating, ventilating and air conditioning systems (HVACs), control rooms, air handling units (AHUs), pump sets, extract fans, pipework, ducting and peripheral devices, lift systems (rails, motor, and electrical closet), heat pumps, chillers and cooling towers, compressors, cogeneration plants (CHP).

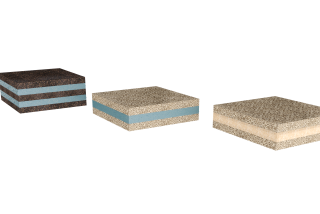

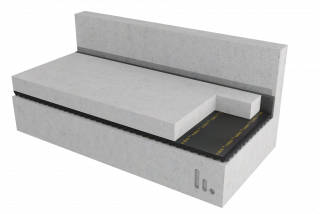

Inertia Bases

Inertia bases, used in conjunction with the right acoustic isolation system, are the most effective anti-vibration technique for machinery isolation.

Inertia bases can be either a simple steel frame or they can consist of large concrete masses or floors which are supported by isolators. The increased mass of the concrete system reduces vibration amplitudes, lowers the center of gravity thereby reducing rocking, increasing thrust resistance, and operating stability.

Inertia bases can be either over an entire floor (floating floor) supporting multiple machines or be a smaller footprint for just one machine or small groups of machines (inertia block).

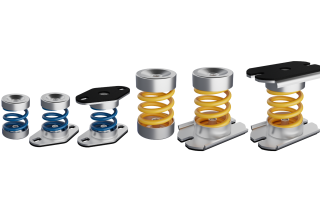

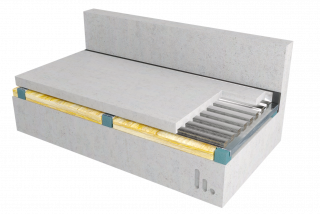

Anti-vibration Mounts

Based on the specific needs of a project and the associated design considerations, one potential approach to isolating building services and mechanical equipment or safeguarding sensitive instrumentation could involve the installation of resilient bearings directly beneath the equipment.

A diverse array of elastomeric bearings (Stravimech Bearing-P), springs (Stravimech Bearing-S) and air mounts (Stravimech Bearing-Air) is available as solution for directly decouple mechanical equipment.

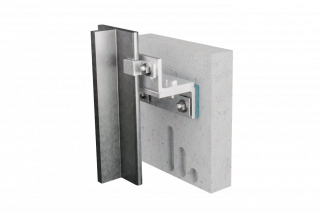

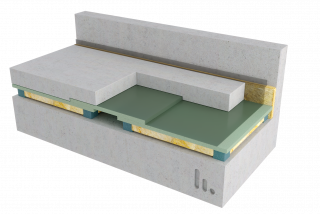

Fixation/Anchoring Systems

Frequently, the need arises not only to decouple equipment from its supporting structure but also to establish an elastic fixation, such as Stravimech Fix, to reduce the transmission of vibrations from the machine to its support. The use of isolated fixation is also a way to protect the decoupled structure or equipment against lateral and eventual dynamic uplifting loads.

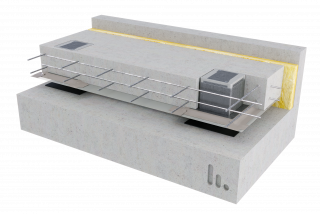

Suspension Systems

The piping and ductwork systems connected to and from the disturbing machinery should receive equal attention to ensure proper isolation. This can be achieved by employing Stravilink resilient hangers to either decouple these systems or suspend the equipment itself. For instance, an increasing number of air handling units (AHUs) are now designed as suspended units, positioned between the suspended ceiling and the structural slab.

Typical examples of where our industrial solutions can be used to minimise the effects of noise and vibration from machinery:

Elevators

As modern cities become increasingly high-rise, buildings require faster more efficient elevators to transport users over higher distances. Every lift has a machine room either pulling or pushing the lift and the machinery within these rooms may require isolation to avoid disturbance to nearby occupants. There is also likely to be a further requirement to isolate the running rails of the lifts to decouple them from the supporting structure in order to minimise structure-borne noise: Stravimech ElevatorFix.

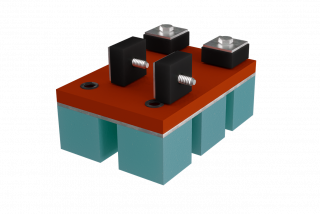

Transformers

The 50Hz hum and harmonics are characteristics of all transformers and this heavily tonal noise and vibration requires careful isolation to ensure it is not audible above background noise levels in nearby sensitive spaces.

Special design Stravimech Bearing-P, Stravimech Bearing-S and Stravimech Bearing-Air are developed for transformers.

Weaving Machines, Metal Presses or Others

Metal and other kinds of material presses exert large impact forces during the production process of various finished products. Industrial textile machinery has advanced significantly over the past few decades and weaving looms are now enormous machines that generate large amounts of vibration and noise. A very successful method of isolation is to locate these machines on large concrete inertia bases to prevent the vibrations disturbing nearby areas and to protect the machine from damage.

-

Information Available to Download

-

Brochure Building Services & Mechanical Equipment (EU)