Main page content

Entity view (Content)

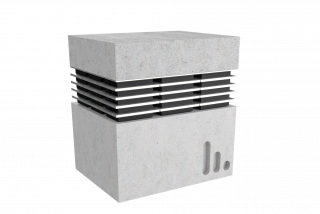

Building Base Isolation

Entity view (Content)

Today’s requirement for sophisticated, highly complex multi-functional buildings within urban spaces is a challenge for designers, as there are many potential risks for noise nuisance which require careful consideration.

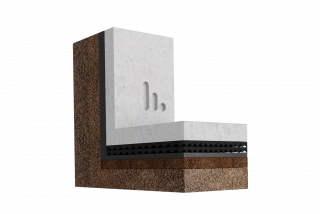

Most new buildings within cities are likely to be located within close proximity of a major source of noise and vibration, such as an underground tunnel, a railway line or a busy road. In order to protect a building from the consequential structure borne noise and vibration it is necessary to decouple it from the source by introducing building base isolation. We offer a range of high-performance noise and vibration solutions for every type of construction and requested performance.

Since the early 1960’s CDM Stravitec has been a pioneer in building base isolation projects all over the world and thereby gained extensive experience. Stravibase is CDM Stravitec brand for building base isolation and elastic fixations.

Main Features

-

High Load Capacity

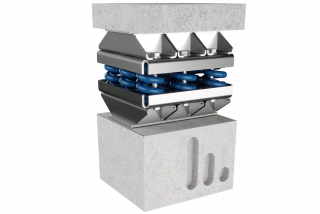

Bearings are designed to support very high loads whilst minimising column size and reducing construction cost.

-

Failsafe

When required, CDM Stravitec solutions can be designed to accommodate failsafe systems to control deflections.

-

Lateral Restraints

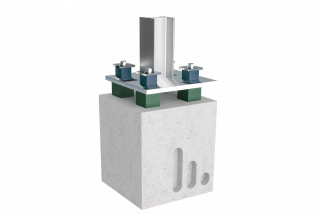

Isolated shear keys, isolated dowels or lateral isolation bearings can be incorporated in the overall design of buildings subjected to lateral loads (mostly from wind).

-

Uplift Restraints

CDM Stravitec can design uplift restraint solutions to provide stability in situations where significant uplift loads can be expected.

-

Fire Resistance

When required, CDM Stravitec can advise a solution for fire protection of the different building base isolation systems. Designs to meet 2-hour fire ratings are available.

-

Replaceability

Replacement strategies can be foreseen when designing building base isolation solutions, being through bespoke assemblies or using our patented Frozen Bearing Technology (see below).

Frozen Bearing Technology

Frozen Bearing Technology (FBT) technique allows CDM Stravitec to replace elastomer bearings without disturbing the building’s structure; which may become necessary if there is a significant change in the imposed load.

Though not present during the first construction phase with design started in 1958 and construction in 1964, I can state that the conservatory rehearsal class rooms, as well as the Blue and Red Concert Hall, respectively part of first and second construction phase, and both founded on “Elephant Feet”, are worldwide known for their acoustic quality with no comfort nuisance from passing trains during cultural events or from any other internal or external source – the “Elephant Feet” do not require any maintenance and do not show any signs of deterioration after more than 50 years of being in operation.

Paul Vermeir

Technical Director deSingel

-

Information Available to Download