Main page content

Entity view (Content)

Balta Group

Entity view (Content)

Textile manufacturer Balta from Sint-Baafs-Vijve has frequently consulted CDM Stravitec to design, manufacture and install their textile machines with floating inertia bases in order to reduce vibration nuisance to neighbouring buildings. A lost formwork system with natural rubber pads resonating at 6 to 7 Hz was the preferred system.

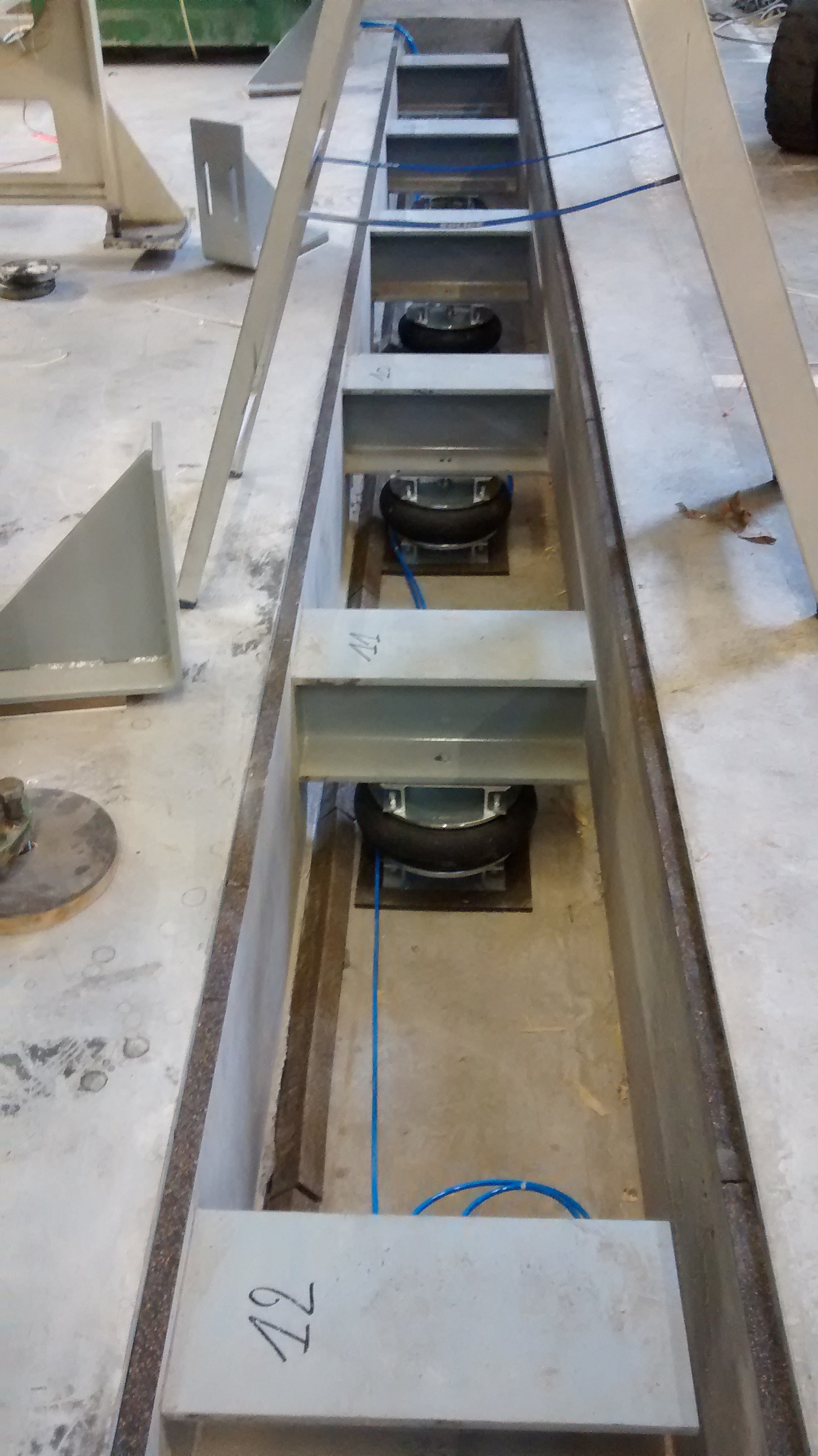

However in 2014 a decision was made to set up one machine on an inertia mass supported by air bellows in order to achieve an improved level of isolation. The results showed a significant improvement i.e. a natural frequency of 3 to 4 Hz. The initial investment cost is easily justified by the reduction in neighbour complaints and improved stability of the loom which in turn results in reduced maintenance and repair costs.

Stravimech Bearing (air mount), an automated pressure-monitoring system, was installed in order to continually calibrate the air bellow system. In the pictures, the air bellows, of which 12 were installed in lateral slots in the concrete, can be seen. The slots were covered with steel sheeting after the air bellows had been installed. The force transmission takes place via I-beams made of steel which are cemented into the inertia mass. The horizontal movements occurring during production are restricted by means of rubber buffers.