Main page content

Entity view (Content)

Wet or Dry Floating Floors in Mass Timber Construction

Entity view (Content)

As mass timber construction continues to gain momentum worldwide, one of the most frequent design challenges remains: should you go for a wet or dry acoustical floating floor solution?

Our latest Technical Bulletin explores this critical choice in depth - weighing up the benefits, trade-offs, and performance results of both approaches.

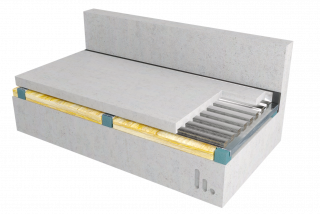

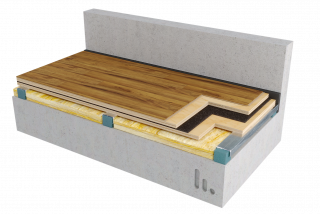

- Wet solutions (concrete, screed, or gypsum toppings) deliver robustness, a durable walking surface, mass, and superior vibration control while also providing fire and moisture protection and being more flexible, making it easier to incorporate heating systems. They are proven performers, though they add weight, complexity, limited design flexibility post-installation and embodied carbon.

-

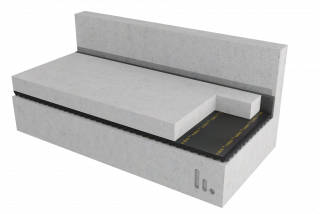

Dry, panelised solutions offer speed, flexibility, and circularity. Lightweight and easily adaptable, they allow services to be integrated in the floor void and can be dismounted for future changes or access to services - aligning with modern sustainable design principles.

But which is best for your project?

The answer isn’t straightforward. Our research shows that both solutions can achieve excellent acoustic performance, each excelling in different aspects.

The Technical Bulletin also presents side-by-side test data from CDM Stravitec’s own developments - including systems with discrete resilient support and roll-out solution, such as Stravifloor Deck, Stravifloor Channel and Stravifloor Mat - giving design teams a clear view of how different assemblies perform in real-life conditions.

Fill out the form below to request access to the free complete technical document and get access to detailed comparisons, acoustic test results, and design considerations to help you make informed decisions on your next mass timber project.

Get your copy

Fill the form below and get the Technical Bulletin Wet or Dry Floating Floors in Mass Timber Construction delivered straight to your inbox.