Main page content

Entity view (Content)

Koelmalaan

Entity view (Content)

In Alkmaar on Koelmalaan stands one of the largest wooden residential buildings in the Netherlands. The development consists of two buildings with 5 floors each, totalling 129 apartments. The residential buildings are constructed from 260 prefabricated CLT modules. These prefabricated modules are made in the factory of Houten Gebouwen.

Housing corporation Woonwaard deliberately chose timber module construction in cooperation with Finch Buildings. By doing so, they opted for speed, sustainability and circular construction. The wooden buildings maintain their quality and value over time. Moreover, the buildings are fully demountable, reusable, relocatable and the modules can be rearranged when a new situation presents itself.

Cross-laminated timber (CLT) made from sustainably managed forests was used to make the units. This environmentally friendly alternative to concrete is rapidly gaining popularity. By using CLT instead of concrete, about 4,800 tonnes of CO2 will be saved in this project. In addition, wood naturally stores CO2, which in this building is about 1,600 tonnes of CO2.

The modules are produced entirely in De Groot Vroomshoop’s Wooden Buildings factory. Ready-made, including bathroom, windows and doors, electricity, insulation, flooring, facades and roofs. From the factory, the modules are transported to the building site to be assembled into a residential building. This construction method is more efficient and safer.

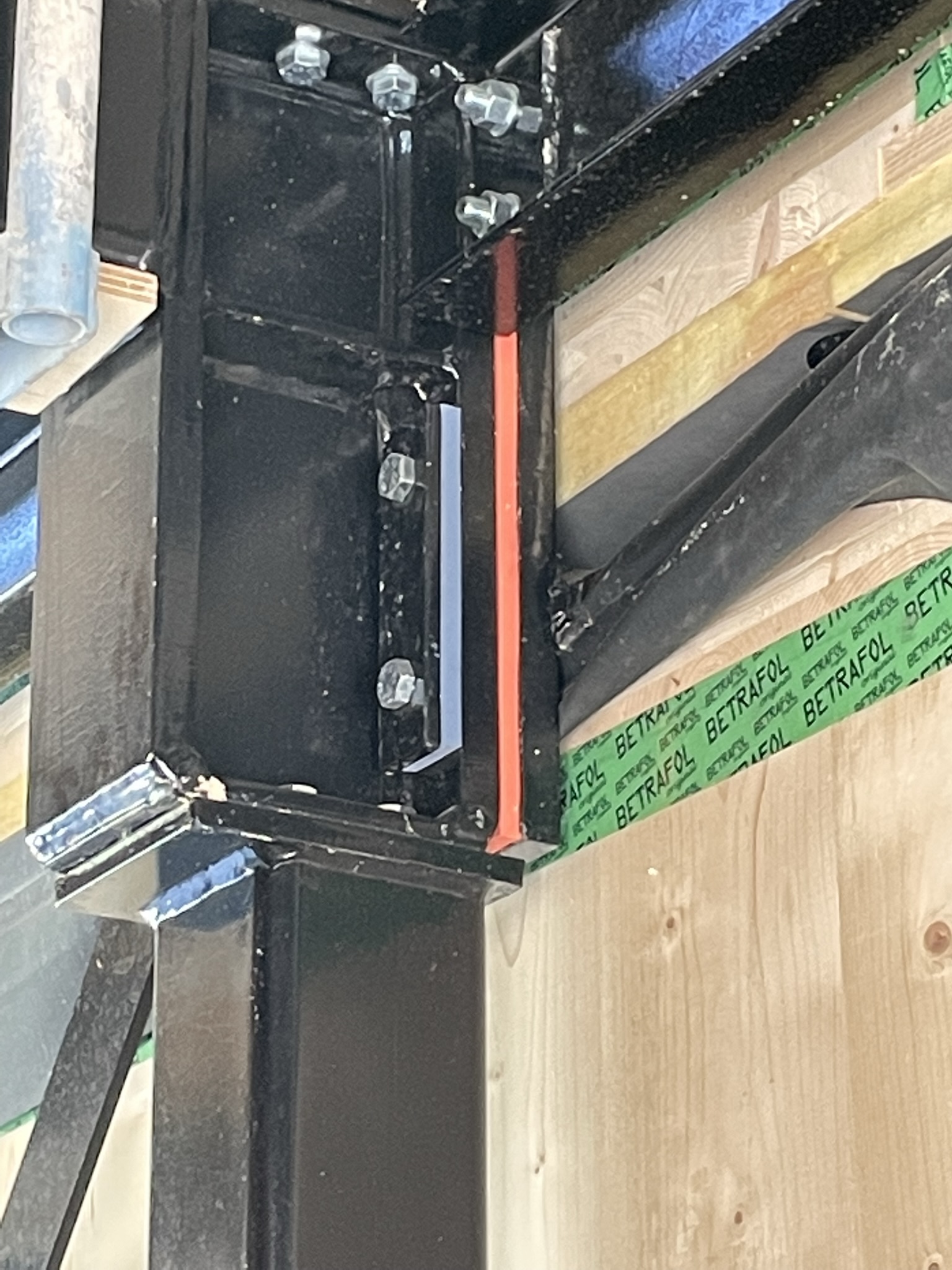

Our local partner Delta-L made sure that the stacked modules are all acoustically decoupled to achieve high impact sound insulation. To do this, the units were placed on top of Straviwood ModuBreak polyurethane foam supports.

Straviwood ModuLink isolators fix the wooden modules horizontally. The elevator on the other hand, is decoupled using Stravibase Fix isolators. To reduce impact noise coming from people walking on the galleries, the wooden gallery floor has been decoupled with rubber granulate pads under the wooden beams.

Request our White Paper now!

In preparation for this project, a test arrangement was made with two 3D modules in cross-laminated timber to test them with various ways of interconnection.

Find more about the findings on this on-site test campaign that allowed the selection of the best solution for this project by getting your copy of a white paper on this matter.