Main page content

Entity view (Content)

Stravifloor Jackup-E

Entity view (Content)

Jack-up floating floor using embedded bell-shaped housing

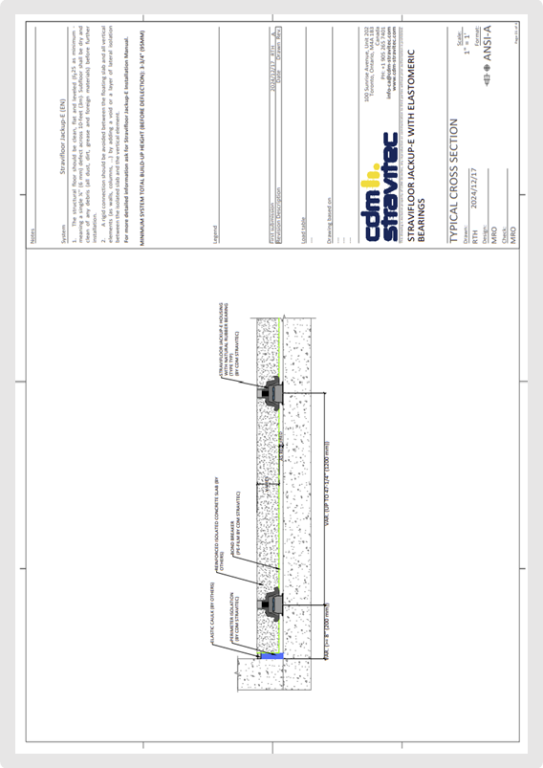

Stravifloor Jackup-E is a jack-up isolated floating floor system using moulded natural rubber within bell-shaped cast iron housings cast into concrete and jacked up after the concrete has cured, to provide the required void depth.

Once the concrete has cured, the isolated slab is raised off the structure to the required void depth. Stravifloor Jackup-E boxes allow for easy adjustment of the final floor height.

Stravifloor Jackup-E is a cost-effective solution with minimal risk of acoustic bridging between the floating floor slab and the subfloor.

-

High Performance

Standard solutions available with moulded natural rubber resilient pads in two standard grades: Pad-L (low stifness), Pad-M (medium stifness). Resilient pads with a maximum service load up to 2,495 lbs (11 kN), achieving a natural frequency of ≤ 10 Hz.

-

Jack-up System

The isolated slab is raised off the structure to the required void depth once the concrete has cured.

-

Low Risk of Acoustical Bridging

Provides the least amount of contact points reducing the potential for acoustical bridging.

-

Easy & Quick Installation

Fairly easy to install as there is no need to fit unusual contours. It has few components, reducing the time needed to install it and limiting the risk of installation errors.

Main Characteristics

- Using cast iron housing with load capacity up to 11 kips (49 kN)

- Standard solutions available with moulded natural rubber resilient pads in two standard grades: Pad-L (low stifness), Pad-M (medium stifness)

- Resilient pads with a maximum service load up to 2,495 lbs (11 kN) and capable of achieving natural frequency ≤ 10 Hz

- Standard design is for 3-3/8'' (85 mm) thick floors. The housing can be fitted with a height extension unit for thicker floating floors

- Two levels of positioning support for reinforcing bars

- Elastomers identified with a colour code to minimize possible installation errors

Main Benefits

- No need for formwork

- The spacing between the bearings isn’t depending on the bending strength of the formwork panels, and therefore the distance between the isolators is determined by the thickness of the floating floor slab and its reinforcement, as well as by the load bearing capacity and the box in which they are placed

- Ensure that the floating floor is decoupled from the substrate to reduce the risk of acoustical bridging. The whole slab is lifted (there is no opportunity for any debris to be left in the cavity and any bridging is broken when the slab is lifted up)

- Before the slab is raised, the area can be used as storage during construction or heavy equipment can be rolled into position, without compromising the system’s performance

- System total build-up height is not dependent on the thickness of the bearing (since elastomeric isolator is located within the housing), allowing for low-profile floating floor systems

- Allow to change the total build-up height without having to change the thickness of the bearing

- Easy to install and low labour cost, no need to fit unusual contours

- Fewer components and lower volumes to be transported, meaning a smaller transport cost and a positive impact on the environment

- Adjustable air void

- Possible solution for vibration, sound and impact isolation

-

Information Available to Download

-

Brochure - High-Performance Floating Floors (US-CA)

-

Typical Cross Section - Stravifloor Jackup-E (US-CA).dwg

-

Typical Cross Sections - Stravifloor Jackup-E (US-CA).pdf

-

Installation Manual - Stravifloor Jackup-E (US-CA)