Main page content

Entity view (Content)

Sky Zone - Trampoline Park - Al Kout Mall

Entity view (Content)

Tamdeen Entertainment Co., established in 2007, is Kuwait’s leading entertainment company, delivering unique leisure experiences across premier shopping malls. Sky Zone, located in The Assima Mall and Al Kout Mall, is an international trampoline park franchise offering wall-to-wall trampolines, foam pits, dodgeball courts, obstacle courses, fitness classes, and venue hosting.

With over 200 locations worldwide, Sky Zone provides a fun, safe, and active environment for individuals, families, and groups.

The Sky Zone project in Al Kout Mall spans 860 m² (9,257 ft²) and is divided into two primary areas: the Court and the Platform. Both zones are fixed directly to the structural slab via steel base plates and columns.

Dynamic activities in the park, particularly trampoline jumps, demanded a high-performance acoustic solution to isolate vibrations and impacts, while addressing the concentrated and uneven load distribution transmitted to the structure through the steel columns.

The Sky Zone project in Al Kout Mall presented a significant acoustic challenge: the trampoline park is divided into two main areas - Court and Platform - both fixed directly to the structural slab through columns and steel base plates. This arrangement creates a direct path for structure-borne noise, requiring a carefully engineered solution.

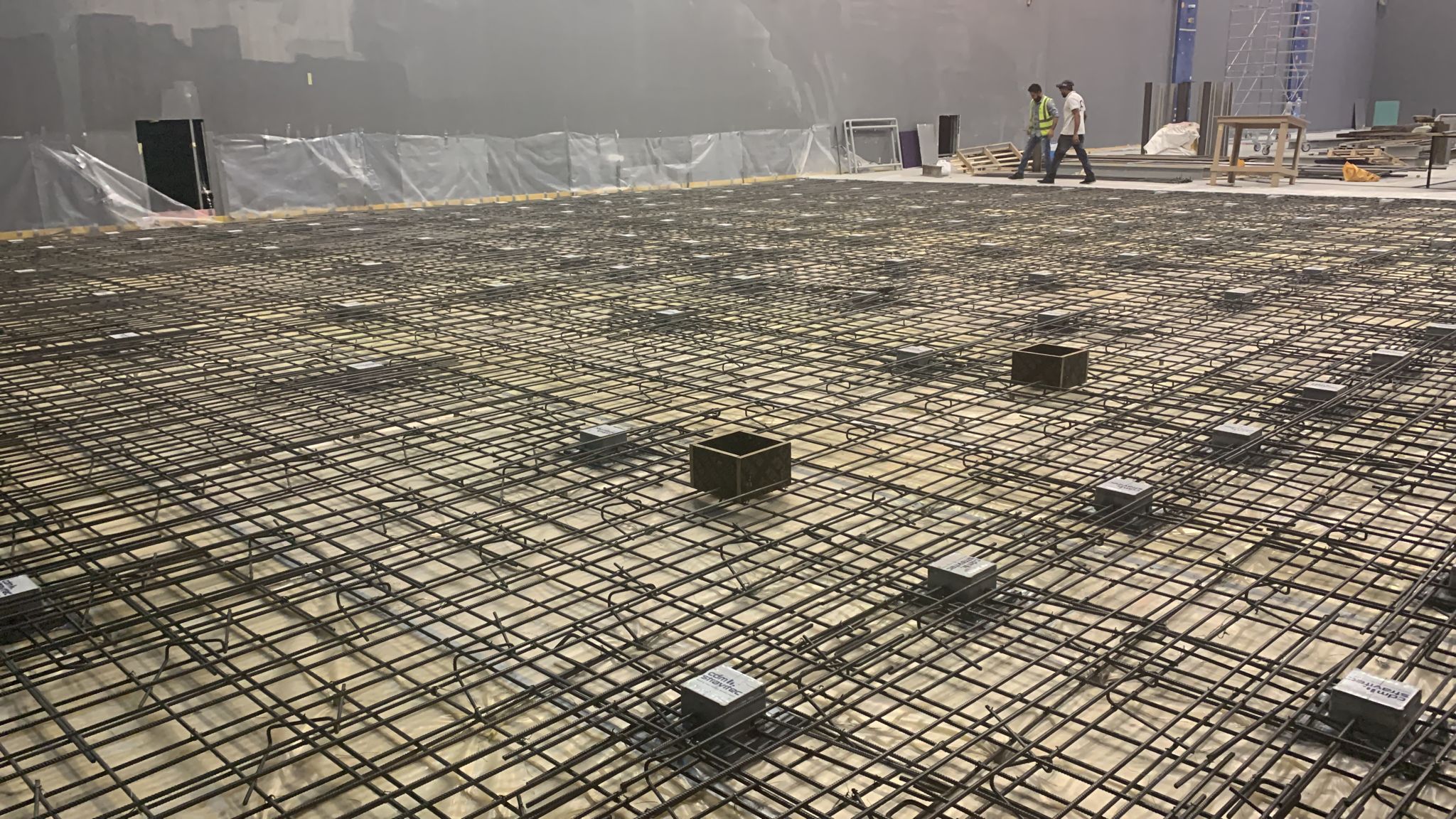

To address this, CDM Stravitec implemented a Stravifloor Jackup-R floating floor system supported by springs beneath the Court and Platform areas, with all base plates fixed to the floating system. The floating concrete slab was designed to achieve a natural frequency of 3.15 Hz, optimized to mitigate vibrations generated by trampoline activities while ensuring structural integrity under variable loads.

To validate the design, CDM Stravitec conducted a finite element analysis (FEA). The analysis modeled the concrete slab with quad8 shell elements, approximating a long-term Young’s modulus of 10 GPa (1.45 Mpsi), while the springs were represented as 1D elements grouped in boxes containing 1, 2, or 4 springs depending on the load and location. Each spring was designed as a multiple of 220 N/mm (1,256 lb/in), allowing the system to accommodate the specific design loads defined for each base plate.

The floating slab was divided into three segments with two construction joints across the floor area, balancing construction practicality with performance optimization. Empty Stravifloor Jackup-R boxes were embedded to allow future levelling adjustments if required, providing flexibility to maintain long-term precision.

Additionally, the void beneath the floating slab was filled with insulation material, enhancing overall acoustic performance by reducing airborne noise and complementing the vibration isolation provided by the spring-mounted slab.

This combination of insulation, tailored spring configuration, and modular segmentation ensures robust noise and vibration control, delivering a safe, comfortable, and acoustically optimized environment for trampoline activities while protecting the surrounding structure from both structure-borne and airborne noise.