Main page content

Entity view (Content)

8 Reasons to Use a Jack-up Floating Floor

Entity view (Content)

What is a jack-up floating floor?

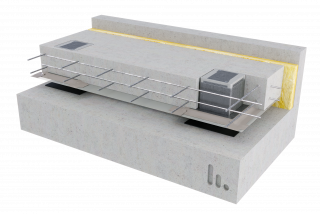

As the name suggests, jack-up floating floors are isolated floating floor systems using boxes, holding either spring or rubber isolators, that are cast into a concrete slab that, once cured, is raised or ‘jacked up’ to create an air void and decouple the entire slab from the structural floor slab.

These systems are recommended where there is a need to reduce the transmission of noise, vibration, or impact.

Though often deemed more expensive and difficult to install, jack-up floating floor systems pose a number of benefits over their non-jack-up counterparts, making them favored by acoustical consultants.

Originally designed and long used to isolate individual pieces of industrial equipment, jack-up systems are now widely used to support not only entire mechanical rooms, but also sound quality spaces and sports and fitness areas. High load capacity jack-up mount systems are ideal to support floating concrete floors in many sound-sensitive applications or in spaces where an adjustable air void is required.

Why use a jack-up floating floor?

-

Ensure that the floating floor is decoupled from the substrate

Jack-up floating floor systems are the most fool-proof way to create the air void between the floating concrete slab and structural floor. These systems greatly reduce the risk of acoustical bridging between the two slabs as any connection is broken when the floating slab is lifted and there is no opportunity for any debris to be left behind in the cavity. Before the slab is raised these areas can be used as storage during construction, without compromising the system’s performance.

In addition, some of these systems have an extremely high load capacity allowing for large spans and fewer support points, making it more cost-effective than often thought.

-

No formwork needed

Where once a continuous layer of insulation material served as a pouring surface for the concrete floor, jack-up systems with minimal support points are suitable and present-day alternatives. These discrete systems eliminate the cost and need for formwork.

As the concrete is simply poured around the boxes on a polyethylene sheet on the structural floor, there is no need for formwork. Since no formwork is being used, the spacing between the bearings isn’t depending on the bending strength of the formwork panels, and therefore the distance between the isolators is determined by the thickness of the floating floor slab and its reinforcement, as well as by the load bearing capacity of the bearings themselves and the box in which they are placed. Additional point/linear loads on the floating slab can easily be supported by adding jack-up boxes.

-

Ideal solution for both passive and active isolation

An acoustic floating floor using jack-up boxes can be used to isolate noisy rooms, such as mechanical equipment rooms, from the adjacent spaces or it can be used to isolate a sound-sensitive space from external sources of noise and vibration. These active and passive types of isolation make jack-up floating floors a welcome addition to any acoustic design.

-

Available with either springs or elastomeric bearings

There are jack-up systems available with either springs or elastomeric bearings, achieving a natural frequency as low as 2.5Hz and 6Hz, respectively.

The selection of either type of isolator depends completely on the project requirements.

-

Total build-up height is not dependent on the thickness of the bearing, allowing for low-profile floating floor systems

With jack-up systems the spring or elastomeric isolator is located within the housing, so the thickness of the bearing has little influence on the total build-up height. Combined with the fact that it is a system without formwork, it allows for the installation of a low-profile acoustic floating floor.

Jack-up floating floor systems allow you to change the total build-up height without having to change the thickness of the bearing, which would increase the frequency of the isolator.

-

Easy to install and low labor cost

Jack-up mount systems are fairly easy to install as there is no need to fit unusual contours. Once the boxes are laid out according to the shop drawings, it is simply a matter of installing a reinforcement grid and pouring the concrete. The concrete flows arounds the housings and into any odd shape or corner, saving considerable installation time.

This type of floating floor system has few components, reducing the time needed to install it and limiting the risk of installation errors and costs related to later repairs. Fewer components and lower volumes to be transported also mean a smaller transport cost, which in turn has a positive impact on the environment.

-

Accessible and replaceable

There are jack-up floor systems that make use of accessible cast housing elements that can be opened after installation. This type of systems allows the customer to inspect, adjust and replace the spring or elastomeric isolators when needed (e.g. changing load conditions).

-

Adjustable air void

Jack-up isolated floating floor system usually uses reinforced steel or cast-iron boxes that are cast into concrete and jacked up once the concrete has cured, to create the required void depth. This lifting-method not only reduces the risk of acoustical bridging, but gives the customer maximum flexibility.